Driven piles do not sit on compressed earth to hold your house up. Instead, they create a bulb of pressure around the piles that work in the same way as a nail being driven into a piece of wood. The nail holds because of the increased pressure around the nail caused by hammering the nail into the piece of wood.

Square nails were used in the early days of construction. However, a square nail may and can loosen over time. A round nail maintains its position almost forever. It is very much the same when installing piling systems.

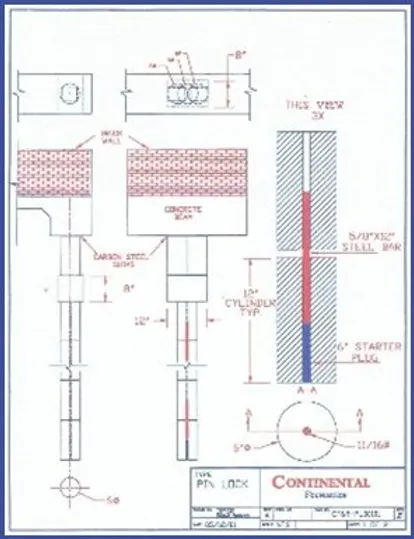

Pin lock is one of the original locking pile systems available in the Houston area. Developed by the founder of Continental Foundation Restoration, James Ogden and foundation repair specialist, Frank Riley, and certified by local independent engineering consultants, pin lock takes the commercial grade driven pile system to the next level of dependability.

Pin lock uses multiple pieces of steel rebar. The rebar works in several methods to strengthen the piling system. First, it verifies that concrete piles have been driven straight and true. Second, it ensures that all piles are fully intact throughout the entire stack. Should one of the cylinders break, the rebar will not fully insert into the cylinder.

Third, the steel rebar virtually guarantees that long-term, concrete piles will stay in alignment and maintain the elevation for the life of the structure. Once pin lock pilings are installed, your home can be leveled that day minimizing your total construction time.

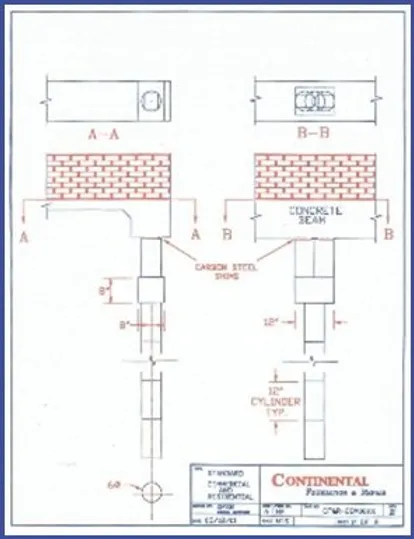

No longer installed by CFR, these concrete cylinders are driven into the ground under your home’s foundation by using the weight of your structure as a counterbalance. Hydraulic rams are used to drive these pre-formed, extremely hardened concrete cylinders, into the earth. The diameter of the cylinder as well as position of each pile are job specific.

The depth of each pile stack is dependent on the weight of the structure being supported, as well as the makeup of the soil beneath the structure. All piles are driven to absolute refusal. This means that the coefficient of skin friction is equal to the weight of the structure above the pile stack.

Placement of pile stacks determines the percentage of structural weight supported by each pile stack. However, we have determined that pin lock piles far exceed non-locking piles in long-term stability tests. Continental Foundation will only offer “PIN LOCK PILES” to our clients.

No longer installed by CFR, these concrete cylinders are driven into the ground under your home’s foundation by using the weight of your structure as a counterbalance. Hydraulic rams are used to drive these pre-formed, extremely hardened concrete cylinders, into the earth. The diameter of the cylinder as well as position of each pile are job specific.

The depth of each pile stack is dependent on the weight of the structure being supported, as well as the makeup of the soil beneath the structure. All piles are driven to absolute refusal. This means that the coefficient of skin friction is equal to the weight of the structure above the pile stack.

Placement of pile stacks determines the percentage of structural weight supported by each pile stack. However, we have determined that pin lock piles far exceed non-locking piles in long-term stability tests. Continental Foundation will only offer “PIN LOCK PILES” to our clients.

Cost:

you will use less square blocks to meet initial refusal than in a round cylinder system.

Speed:

fewer blocks mean less time pressing concrete in the ground.

Profit:

lower labor costs and less material used on the job relate to higher profits.